English

English 简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Why Is a Side Slip Tester Critical for Modern Vehicle Safety?

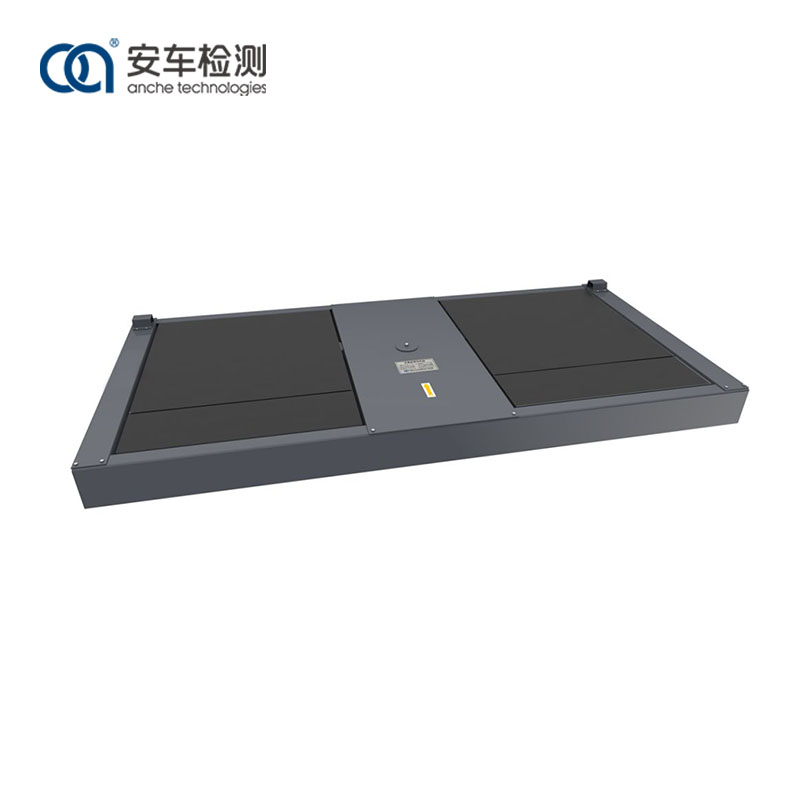

A Side Slip Tester is an advanced diagnostic instrument used to measure a vehicle’s lateral displacement while driving in a straight line. In professional automotive inspection centers, tire shops, and maintenance facilities, this device plays a central role in evaluating wheel alignment accuracy, tire condition, and chassis stability.

What Is a Side Slip Tester and How Does It Function?

A Side Slip Tester measures the deviation of a vehicle’s wheels over a specified distance to assess alignment and overall driving stability. When a vehicle passes over the measurement plate, sensors calculate whether the car drifts left or right. This drifting distance—referred to as side slip value—directly reflects suspension performance, tire balance, steering accuracy, and axle alignment.

The device is widely used in:

-

Vehicle inspection stations

-

Professional alignment service shops

-

Automotive testing laboratories

-

Fleet maintenance centers

-

Tire service facilities

It ensures that vehicles maintain safe travels on roadways by detecting misalignments before they lead to excessive tire wear or compromised handling.

Key Product Parameters (Sample Specification Table)

| Parameter | Description |

|---|---|

| Measuring Range | –15 mm/m to +15 mm/m |

| Test Speed | 5–10 km/h |

| Maximum Load Capacity | 3.5 tons / customizable for heavy-duty vehicles |

| Accuracy | ±0.5 mm/m |

| Sensor Type | High-precision digital displacement sensors |

| Plate Dimensions | 1000 mm × 500 mm × 50 mm |

| Operating Temperature | –10°C to 50°C |

| Output Display | Digital console with real-time side slip values |

| Communication Interface | RS-232 / USB / optional wireless module |

| Installation Requirements | Flush-mount pit installation or ground-level platform |

These specifications demonstrate the tester’s engineering sophistication while ensuring compatibility with both standard passenger vehicles and light commercial fleets.

Why Do Automotive Facilities Rely on Side Slip Testers?

Modern automotive safety depends heavily on reliable suspension geometry, accurate wheel alignment, and consistent lateral stability. A Side Slip Tester provides measurable advantages that make it indispensable for high-quality vehicle diagnostics.

Ensures Driving Stability

A small deviation in wheel alignment can significantly affect handling. By detecting abnormal lateral drift, technicians can identify alignment issues early to safeguard driver stability and vehicle responsiveness.

Reduces Tire Wear Costs

Misalignment causes uneven tire wear, shortening tire lifespan. With accurate slip readings, service centers help customers reduce replacement frequency and avoid inconsistent tread patterns.

Supports Regulatory Vehicle Inspections

Many regions require routine vehicular safety checks. Side Slip Testers help facilities comply with standardized testing criteria, ensuring that vehicles meet alignment and roadworthiness regulations.

Prevents Long-Term Chassis Issues

Chronic misalignment may place stress on steering components, bushings, and suspension joints. Regular slip testing can reveal hidden issues before they escalate into costly repairs.

Enhances Workshop Efficiency

The tester provides quick, accurate readings without complex setup. Shops reduce diagnostic time, enabling faster service cycles and improved customer satisfaction.

These benefits highlight why the Side Slip Tester remains a cornerstone device in professional automotive environments.

How Does a Side Slip Tester Improve Practical Service and Operational Workflow?

The technology behind the Side Slip Tester integrates mechanical engineering with digital diagnostics to create a streamlined testing process.

Straightforward Testing Procedure

-

The vehicle approaches the testing area at a steady speed (typically 5–10 km/h).

-

As the wheels pass over the instrument’s measurement plate, sensors capture lateral displacement.

-

The digital console displays real-time deviation values.

-

Technicians interpret the results to determine whether alignment correction is needed.

High-Precision Sensors for Consistent Results

Advanced displacement sensors detect minute horizontal movements to produce data with high repeatability. This minimizes discrepancies caused by human factors and environmental conditions.

Compatibility With Alignment Systems

Most testers can be integrated with existing alignment equipment, allowing workshops to create a complete diagnostic workflow that includes:

-

Wheel alignment

-

Suspension testing

-

Brake force measurement

-

Tire balancing checks

Durable Industrial Design

Manufactured with reinforced steel and corrosion-resistant plating, modern testers withstand daily high-load operations in busy automotive shops.

Digital Connectivity for Data Management

With upgraded communication interfaces, test data can be:

-

Printed

-

Stored in service records

-

Shared with customers

-

Integrated into workshop management systems

This contributes to a more transparent service process where customers can clearly understand diagnostic results.

What Future Trends Will Shape Side Slip Tester Technology?

The automotive industry continues to evolve rapidly with electrification, autonomous systems, and stricter safety regulations. Side Slip Testers must adapt to support advanced vehicles and smart workshops.

Integration With AI-Based Predictive Systems

Future testers may analyze slip patterns over time to predict potential alignment issues before symptoms appear.

Compatibility With EV and Hybrid Chassis Designs

Electric vehicles have unique weight distribution and tire characteristics. Next-generation testers will be calibrated for EV-specific parameters to handle:

-

Heavier battery packs

-

Specialized suspension geometry

-

High-torque drivetrains

Wireless Data Ecosystems

Wireless communication modules will support seamless connection to cloud-based workshop management systems, enabling long-term tracking of fleet performance.

Enhanced User Interface and Touchscreen Displays

Improved visual diagrams and digital reports will help technicians interpret data more clearly and assist customers in understanding service needs.

Automated Inspection Lines

As automated vehicle inspection lanes become more widely adopted, Side Slip Testers will function as integrated, self-managed modules in smart inspection facilities.

These evolving trends indicate the essential role of Side Slip Testers in meeting the rising demands of future automotive safety and efficiency.

Common Questions About Side Slip Testers

Q1: What does a side slip value indicate during a vehicle inspection?

A side slip value indicates whether the vehicle is drifting laterally during forward motion. A positive or negative reading shows deviation to the right or left, and the magnitude reveals the severity of misalignment. This data helps technicians diagnose whether steering geometry, suspension components, or tire balance requires adjustment.

Q2: How often should vehicles undergo side slip testing?

Side slip testing is recommended during routine maintenance, especially when symptoms such as uneven tire wear, steering pull, or vibration occur. Fleet vehicles and commercial cars benefit from more frequent testing due to higher mileage and operational demands.

Enhanced Safety with Anche’s Professional Side Slip Tester

The Side Slip Tester remains an essential diagnostic tool for ensuring vehicle stability, prolonging tire life, improving steering accuracy, and supporting standardized safety inspections. As the automotive landscape continues to evolve—driven by electrification, digital diagnostics, and intelligent workshop systems—reliable side slip measurement becomes even more critical.

Anche provides high-quality Side Slip Testers engineered for accuracy, durability, and seamless workshop integration. For organizations seeking dependable solutions backed by advanced manufacturing, professional calibration, and long-term support, Anche stands as a trusted partner in automotive diagnostic technology.

For further information or product inquiries, contact us to receive professional assistance tailored to your operational needs.