English

English 简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

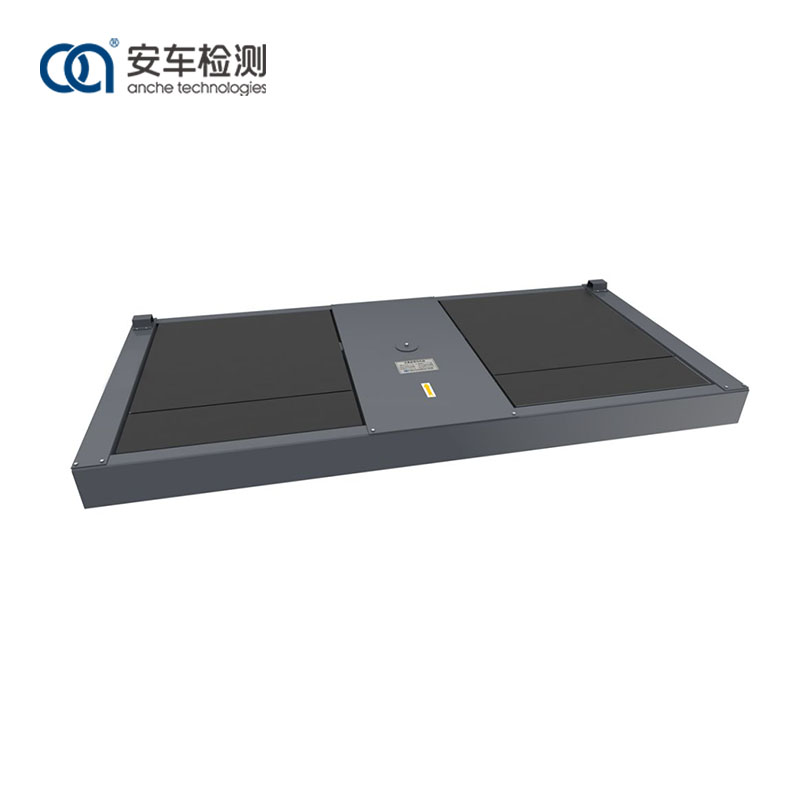

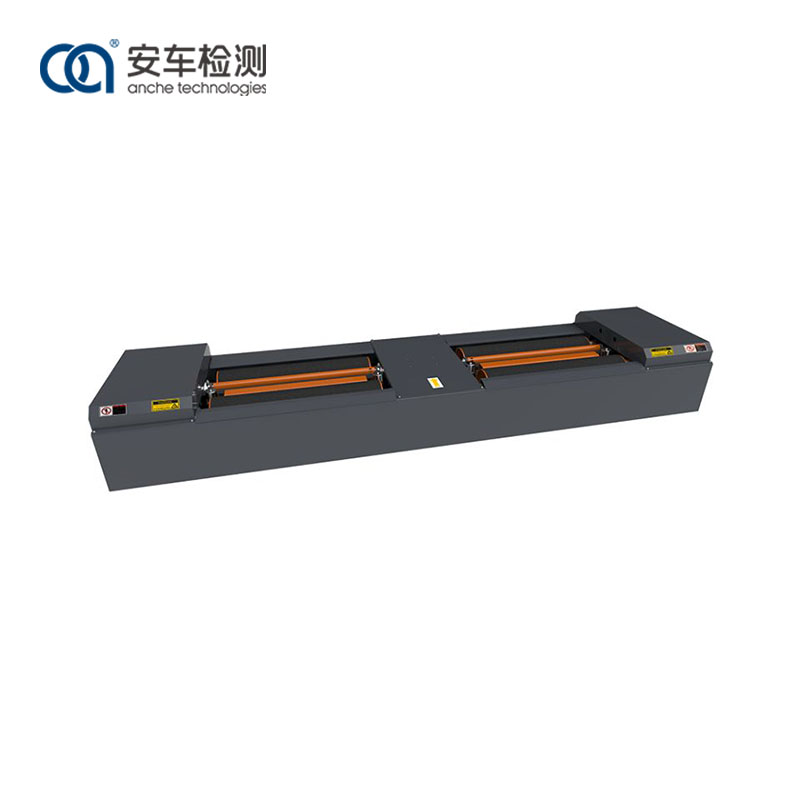

10-Ton Roller Brake Tester

Send Inquiry

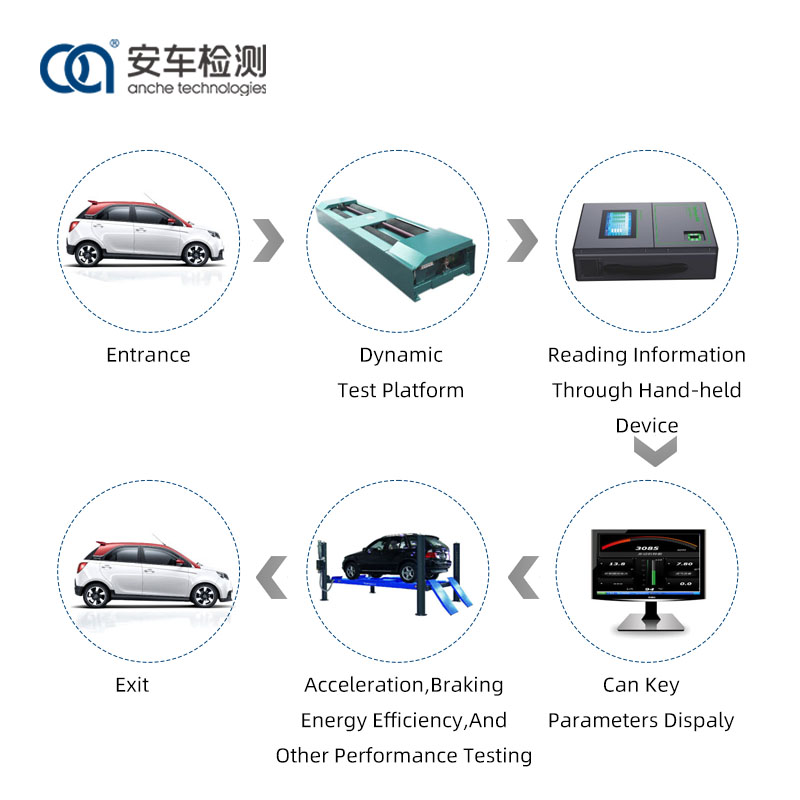

Anche 10-Ton roller brake tester is designed and manufactured strictly in accordance with the Chinese national standards GBT13564 Roller opposite forces type automobile brake tester and JJG906 Roller opposite force type brake testers.

Functions and features:

Anche 10-Ton roller brake tester can test the maximum braking force of the wheels, wheel retarding force, braking force balance (difference between the braking forces of left wheel and right wheel) and braking coordination time, thus evaluating the braking performance of single axle and the whole vehicle.

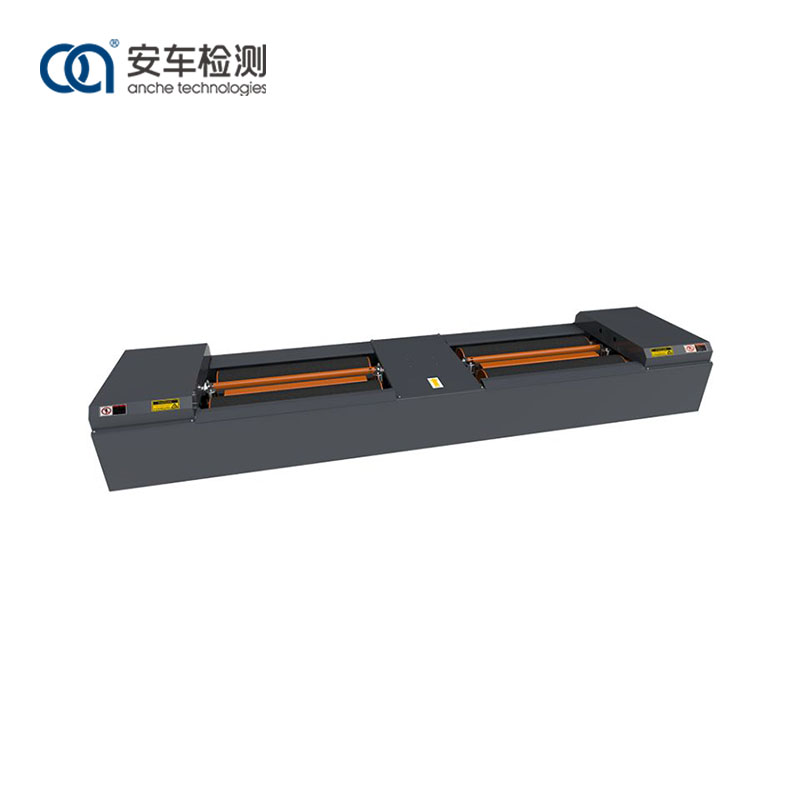

It adopts uneven roller design, and stops the motor with the third roller to reduce the abrasion of the roller in the testing process;

The surface of the roller is treated with corundum, and the adhesion coefficient is close to the actual situation of the road surface;

High-precision braking force sensor is adopted;

It uses unique lifting device, to reduce the impact of vehiclesto the equipment, and facilitate the departure of the vehicles.

Test speed is optional: 2.5-5.0km/h

Working principle of the lifting beam:

For the convenience of vehicles entering and exiting the tester, the device is equipped with left and right independent airbag lifting beams. Before the vehicle drives onto the brake tester, the photoelectric switch does not read the in-place information of the vehicle, and then the airbag lifting beam rises, allowing the vehicle to smoothly enter the device; when the photoelectric switch receives the in-place signal, the system sends a command, the lifting beam descends, and the wheels rotate with the roller for inspection; after the inspection is done, the independent airbag lifting beam rises and the vehicle drives smoothly out of the tester.

Working principle:

The motor is specially designed and manufactured to ensure that the maximum braking force on the roller meets the requirements of the rated loading capacity. The motor gear torque box has reliable strength and sufficient torque. The motor drives the roller sets through the torque box to rotate the vehicle wheels. When the wheels brake, the reaction force between the tire and the roller causes the torque box to swing. The braking force is converted into an electrical signal output through the force measuring lever at the front end of the torque box and the pressure sensor installed on it. After being processed by the electronic control system, it can be displayed through the control system.

Characteristics

1) It is welded from a solid square steel pipe and carbon steel plate structure, with precise structure, high strength, and resistance to rolling.

2) It adopts a high and low roller design, with the third roller stop motor technology, reducing tire wornness caused by the roller during the inspection process.

3) The surface of the roller is treated with corundum, and the adhesion coefficient is close to the actual situation of the road surface.

4) High precision brake force sensors are selected as the measuring components, with precise and accurate data.

5) The signal connection interface adopts an aviation plug design, which ensures fast and efficient installation, stable and reliable data

Application

Anche 10-Ton roller brake tester is suitable for different industries and fields, and can be used in the automotive aftermarket for maintenance and diagnosis, as well as in motor vehicle test centers for vehicle inspection.

Parameters

|

Model |

ACZD-10 |

ACMZD-10 (for both carsand motorcycles) |

|

Allowable axle load mass (kg) |

10,000 |

10,000 |

|

Measurable maximum braking force (N) |

30,000×2 |

3,000×2 /3,000 (motorcycle) |

|

Braking force indication error |

<±3% |

<±3% |

|

Roller size (mm) |

ф245×1050 |

ф245×1050(long) ф195×300(short) |

|

Inner span of the roller (mm) |

700 |

700 |

|

Outer span of the roller (mm) |

2800 |

2800 |

|

Center distance of the rollers (mm) |

447 |

469/300 |

|

Motor power (kw) |

2×11kw |

2×11kw (car) /0.75kw (motorcycle) |

|

Boundary dimension (K*W*H) mm |

4000×960×400(the height is 535withplate cover) |

3940×960×761 (the height is 855with platecover) |

|

Roller surface form |

Corundum |

Corundum |

|

The third roller |

Yes |

Yes |

|

Working air pressure (MPa) |

0.6-0.8 |

0.6-0.8 |

|

Liftingmethod |

Airbag lifting |

Airbag lifting |

|

Motor power supply |

AC380V±10% |

AC380V±10% |

|

Sensor power supply |

Details