English

English 简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Car Suspension Tester

Send Inquiry

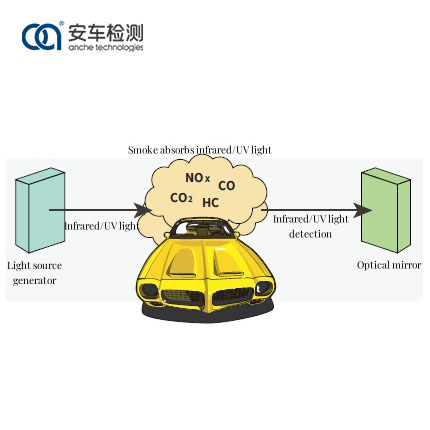

Working principle of Car Suspension Tester:

The vehicle is parked at the designated position and is forced to vibrate on the tester and the suspension device of the vehicle through an exciter composed of an electric motor, eccentric wheel, energy storage flywheel, and spring. After turning on the tester for a few seconds, disconnect the power supply to the motor, thereby generating sweep frequency excitation from the energy storage flywheel. Due to the higher frequency of the motor compared to the natural frequency of the wheel, the sweeping excitation process of the energy storage flywheel gradually decelerating can always sweep to the natural vibration frequency of the wheel, causing resonance in the test plate and the vehicle. By detecting the vibration curve of force or displacement during the vibration attenuation process after excitation, the frequency and attenuation characteristics can be determined to determine the performance of the suspension damper.

Characteristics:

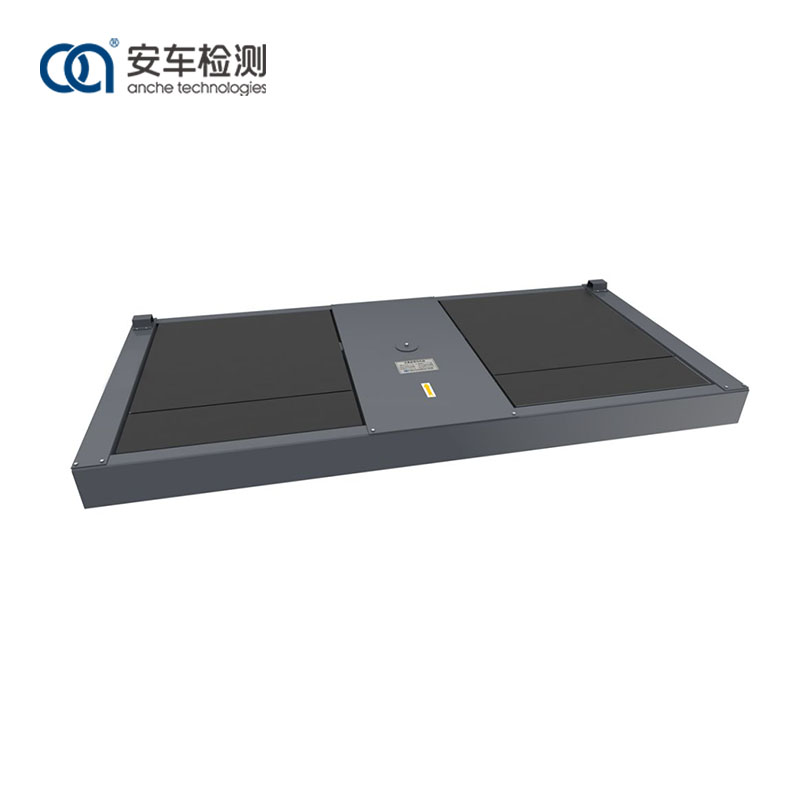

1) It is welded from a solid square steel pipe and carbon steel plate structure, with a sturdy structure, high strength and beautiful appearance.

2) The measurement components use high-precision force and wheel load sensors, with precise and accurate data.

3) The signal connection interface adopts an aviation plug design, which ensures fast and efficient installation, stable and reliable data.

4) It has strong compatibility and can be compatible with different vehicle models for testing.

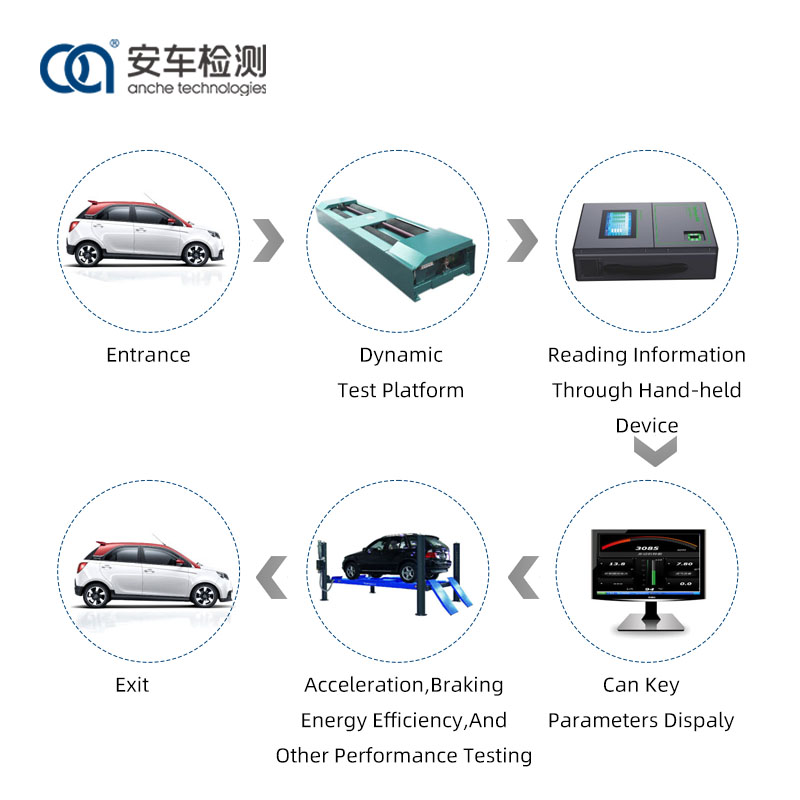

Application

Anche car suspension tester is designed and manufactured strictly in accordance with the Chinese national standard JT/T448-2001 Automotive suspension tester and JJF1192-2008 Calibration specification for automotive suspension tester. It is logical in design, durable in its components, precise in measurement, simple in operation, comprehensive in functions, and clear in display. The measurement results and guidance information can be displayed on the LED screen.

Anche car suspension tester is suitable for different industries and fields, and can be used for maintenance and diagnosis in the automotive aftermarket, as well as for vehicle inspection at test centers.

Parameters:

|

Model |

ACXJ-160 enhanced type |

|

Maximum axle load mass (kg) |

10,000 |

|

Maximum test wheel load (kg) |

2,000 |

|

Absorption repeatability |

≤3% |

|

Weighing indication error |

±2% |

|

Dimension (L×W×H) mm |

2,220×450×329 |

|

Motor power supply |

AC380V±1% |

|

Motor power (kw) |

3KW×2 |

|

Sensor power supply |

DC12V |

|

Weight division value (kg) |

1 |

|

Initial excitation frequency (Hz) |

24 |

Details